BREWING SAKE

& SDGs

BREWING SAKE & SDGs

Sake brewing is SDGs!

Sake brewing, which has a long history, is a truly “sustainable” industry that has inherited the spirit of Japanese manufacturing culture and continues to this day. In the sake brewing process and the relationship with surrounding industries and regions, there are various ingenuity and wisdom of coexistence with nature. At the Hyogo Sake Brewers Association, we will learn from the spirit and efforts of the "SDGs" that our predecessors have cultivated, and will continue to work on the "SDGs" for the next generation.

The Sustainable Development Goals (SDGs:Sustainable Development Goals) are 17 international goals for sustainable development that were unanimously adopted by member states at the United Nations Summit in September 2015.

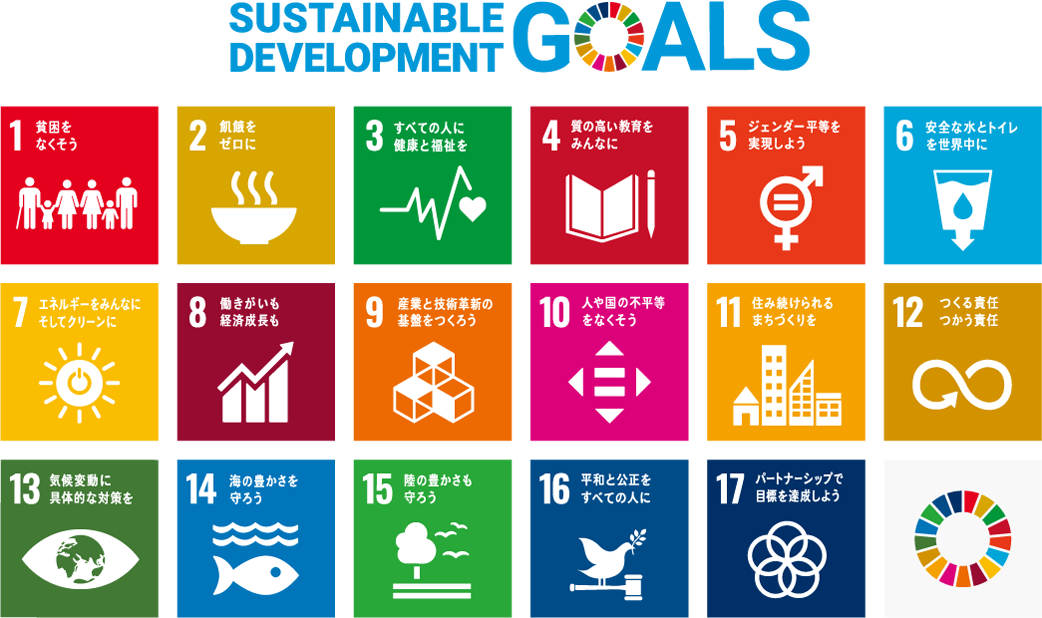

Sake is a sustainable product

Sake brewing has been carried out by circulating the local environment and economy as a recycling-oriented industry, from the procurement of raw materials through the brewing process to the utilization of waste. While changing with the times, the sustainable, recycling-oriented spirit cultivated by our predecessors continues to live on in sake brewing today.

-

1.Material

Sake is made from only the water and rice that can be harvested in the land, and has been brewed with a taste that matches the food of each region. By buying rice grown by local farmers, turning it into sake, and having people buy the sake, the local economy circulates.

-

2.Brewing process

Sake has been made by making good use of the power of nature. Not only is sake itself a product that utilizes the power of fermentation by natural koji mold, but the power of nature is also used in the utensils.

-

3.Utilization of waste

Others have also used things that are unnecessary for sake, which are born during the sake brewing process. For example, the rice straw produced during the rice harvesting process can be used for straw sandals and New Year's decorations, and the "sake lees" produced during the brewing process can be used for amazake (sweet sake) and kasujiru. It has been utilized so as not to throw it away as much as possible.

-

4.Symbiosis with nature

To make delicious sake, you need delicious rice and water. The natural environment in which the rice is grown and the water used for sake brewing, represented by Nada no Miyamizu, have been carefully protected to this day through the cooperation of people involved in agriculture, sake brewing, and the local community.

-

5.Harmonious coexistence with the local community

Sake breweries that use local ingredients to make sake that matches local food are a community-based industry. Local culture is created in various ways and blends into the local community.

Efforts for SDGs in “Hyogo Sake”

Each sake brewery, which is rooted in the region and has been brewing sake in the relationship with the surrounding industry, has therefore appreciated the blessings of the region and valued the connection with the local residents. Hyogo Prefecture, which is the birthplace of Japanese sake and has a long history as the origin of modern sake brewing, such as Itami Morohaku and Nadagogo, has long been engaged in various initiatives that can now be called “SDGs”.

-

walking with the community

In 1920, Mr. Kichizaemon Tatsuma (Tatsuma Honke) founded the ``Tatsuma Gakuin Koyo Junior High School''. In 1927, the former Nada Junior High School was established with the generosity of the Ryokano family and the Yamamura family.

-

Sake Brewing and Yashiro

A toji usually runs a farm in his hometown, and during the sake brewing season, he takes a brewery worker with him to live in a contracted brewery and undertakes sake brewing for one season. The interests of the brewery side, which suffers from a shortage of brewers only during the winter brewing season, were in common, and they were strongly tied to each other in a win-win relationship.

-

No waste of by-products

By-products created in the manufacturing process have been used without waste. For example, rice bran, which is shavings after rice polishing, is used as a raw material for rice bran pickles and livestock materials. Sake lees produced by squeezing sake from moromi have been used in cooking.

-

protect local nature

We have protected the paddy fields through contract farming (Muramai system) with brewer's rice production areas. In addition, each sake brewery operates sake brewing business while protecting the local natural environment, such as continuing to protect the water sources that are essential for sake brewing, such as Miyamizu of Nadagogo.

SDGs that Hyogo sake breweries are working on for the future

- ALL

- Yashiro

- Kakogawa

- Awaji

- Tamba/Sasayama

- Himeji

- Akashi

- Nadagogo

- Itami

- North Hyogo

-

Nihon no Koshukura Inc.

Kakogawa Brewers Association

Click here for details

Click here for detailsNihon no Koshukura Inc. checks the current status of sake breweries across Japan, buys sake that is out of business or has been stored for a long time and is not planned to be sold, stores it, recycles it as old sake and sells it.

In doing so, we support the traditional Japanese industry of sake brewing and contribute to the revitalisation of local economies and the creation of sustainable local economies.

In addition, by giving new value to sake that has been out of business or stored for a long time as old sake, we are working to reduce sake waste and make effective use of it.

In addition, koshu is produced by storing sake at room temperature in a brewery and maturing the sake, which is an environmentally friendly way of producing koshu through energy-neutral and CO2-free brewery operations.

We have established the company with 10 partner sake breweries across Japan to help pass on the culture of old sake, and we also work with 52 sake breweries in 22 prefectures across Japan.

We will continue to work for the future of koshu culture, to promote and enhance the value of koshu, and to make efforts for the development of Japanese sake. -

YAEGAKI Sake&Spirits, Inc.

Himeji Brewers Association

Click here for details

Click here for detailsMaking sake requires a lot of water. In addition to brewing water, the water used for washing and other miscellaneous purposes is 30 to 50 times the amount of water used for the raw rice. Much of the water used is then discharged as wastewater. In particular, the wastewater from washing rice has a large environmental impact and must be discharged after appropriate wastewater treatment. Since 2016, our company has been using micro-organisms to methane ferment the wastewater and other substances generated in the sake production process. This methane fermentation reduces the eutrophic components in the wastewater and produces biogas that can be used more effectively. The biogas extracted from the methane fermentation is then returned to the company as fuel for the boilers used to produce steam and hot water for the steaming of rice and other processes at the factory.

(Photo left) Biogas holder (Photo right) Methane fermenter -

KONISHI BREWING CO., LTD.

Itami Brewers Association

Click here for details

Click here for detailsKonishi Brewery recognises that its 470-odd year history is a series of sustainable activities. Recent activities include the promotion of environmental protection initiatives such as the use of lightweight bottles and environmentally friendly materials, as well as the acquisition of FSSC 22000 certification, an international standard, to ensure that we can always provide 'food safety and security'.

In the first place, the sake brewing industry is aware that the activities required on the planet today are to pass on fermentation techniques and food culture and to protect the 'traditional sake brewing culture'.

In order to contribute more than ever before to the sound development of the region, we will also be involved in the sound upbringing of young people and school education through Shubukan, one of the three largest private dojos in Japan, and work to build the foundations for a better society.

In the brewing industry, which used to be a male-dominated society, we have also placed great importance on the success of women. Currently, the percentage of women in management positions is 26%, far exceeding the Japanese standard of more than 10%. We aim to reach 30% as soon as possible.

Based on the corporate philosophy of "Elegance and Innovation", this phrase is that "the essence of sake will always remain the same in the constant pursuit of newness and challenge.", we will continue to be with the local community in Itami, the birthplace of sake, and develop from our history and traditions to become a world-class company in the future. -

Itami Oimatsu Brewing Co., Ltd.

Itami Brewers Association

Click here for details

Click here for detailsFor sustainable sake brewing, we are committed to environmental considerations and value our relationship with the local Itami community.

・The brewery and sales office have switched to LEDs and energy-saving production lines.

・The company collects and reuses bottles.

・The brewery uses vegetable oil ink containing plant-derived ingredients and paper bags made from recycled paper containing recycled paper pulp.

・Selling sake lees produced in the brewing process and developing curry, bread, rice crackers and other products using sake lees.

・The company has also developed curry, bread, rice crackers and other products using sake lees.

・Work experience for junior high school students during 'Try It Again Week' in the prefecture. -

OKAMURA SHUZOJO

Itami Brewers Association

Click here for details

Click here for details・The raw materials used are sake rice grown in the company's own fields and local sake rice. The brewery sells sake brewed in harmony with nature, using local water and working in cooperation with local people to protect nature.

・The brewery also sells sake lees from the brewing process, and in collaboration with a local pastry chef, it sells pound cakes made from sake lees and soaps containing junmai sake.

・The female head of the brewery is the master brewer, and she is responsible for everything from rice cultivation to sake brewing.

・The brewery is also committed to the environment, using electric forklifts and LED lights to reduce power consumption in the factory, using reusable bottles and returnable P-boxes, taking broken bottles to recycling companies, and separating the polyethylene and aluminium crowns of sake bottles. -

SAKURA SAKE BREWING CO.,LTD.

Tamba Sasayama Brewers Association

Click here for details

Click here for details・We are promoting energy saving by switching to LED lighting in the factory.

・We plant chestnut trees and continue to manage the many cherry and plum trees that have been planted for some time.

・Since 2015, together with Group company Hakutsuru Farm, we have been cultivating Hakutsuru Nishiki and Gohyakumangoku, rice suitable for sake brewing, in our home town of Tanba Sasayama. We use rice produced in Tamba Sasayama City in all of its products, and is working to protect the environment, including land use.

・The rice wastewater generated during the brewing process is treated by micro-organisms in the factory and the residues are composted in the factory. The compost is shared with the Hakutsuru Farm and neighbouring communities, contributing to local agriculture. -

Konotomo Sake Brewery Co.,Ltd.

North Hyogo Sake Brewers Association

Click here for details

Click here for detailsUsually, the large amount of 'sake-kasu' that is always produced in the sake brewing process becomes industrial waste if it remains unsold. In our brewery, sake lees are used as board lees and pickle lees, while the unprocessed sake lees from ginjo sake are used in shochu production. The method is to add the ginjo lees during the shochu making process to dissolve and saccharify them, as well as to ferment them to increase the shochu making rate.

The lees from shochu are also very rich in amino acids, and in 2010 the lees were transferred to the Osaka Prefectural Engei Senior High School, where they are used as part of the food for bee keeping. This initiative was initiated to help break down the situation in the beekeeping industry in Japan, where the horticultural industry is unable to supply the bee swarms it needs, starting with the mass disappearance of honey bees, which is a problem worldwide. As a countermeasure to the shortage of bees, it is particularly important to develop healthy bees, and the beekeeping industry usually uses 'substitute pollen' during periods when flowers are scarce. However, there is no good 'substitute pollen' in Japan, so beekeepers rely on expensive imports. The Osaka Prefectural Engei Senior High School has therefore produced a purely domestic 'substitute pollen'. Shochu lees, which would otherwise have been discarded, are used to nurture bees and play a part in creating a habitable environment. -

Karibaichi Sake Brewery Co., Ltd.

Tamba Sasayama Brewers Association

Click here for details

Click here for detailsKaribaichi Sake Brewery is working to achieve the SDGs goals through the initiatives listed below.

・We are working to preserve the local environment by growing sake rice in our own rice fields near the brewery.

・We are participating in a sake rice project in the Furuichi district of Tanba Sasayama, where our brewery is located, with the aim of creating a SATOYAMA Model that will last for 100 years. In this project, some of the sake rice is grown without pesticides, and other efforts are being made to cultivate the rice in a way that is considerate of the natural environment.

・We are promoting energy conservation by switching to LED lights throughout the brewery.

・We accept local junior high school students to participate in "Try It Again Week," an annual event held in Hyogo Prefecture, to encourage them to become interested in the local community and work through work experience.

・We are working to reuse bottles, collecting not only our own bottles but also those of other companies, washing them, and inspecting them. -

MEIJO SAKE BREWING CO., LTD.

Himeji Brewers Association

Click here for details

Click here for detailsSolar power generation, conversion of wastewater sludge into animal feed, conversion of sake lees into animal feed and fertilizer

-

TAJIME General Partnership

North Hyogo Sake Brewers Association

Click here for details

Click here for details・The lighting in the company will be converted to LED sequentially. We will continue to reduce electricity consumption.

・We will use locally grown rice for all of our sake brewing.

・Since 2005, we have been brewing sake using specially cultivated rice based on the "Stork Breeding Agricultural Method".

This is the first year that we are using the "Stork Breeding Agricultural Method" for sake rice, and we were one of the first to address environmental issues, and we are still working on it. The "Stork Breeding Agricultural Method" is an agricultural method that aims to create a rich culture, region, and environment where storks can live by nurturing delicious rice and a variety of living creatures. For example, to create a habitable environment for living creatures, various techniques are employed, such as "winter waterlogging" to flood rice fields in winter, the use of organic fertilizers from the seedling stage, and safe and secure cultivation using no or reduced pesticides (limited to those with low fish toxicity). We grow living creatures that serve as food for storks, protect storks, and create a rich Tajima.

・We use recycled bottles to protect the environment.

・We sell all sake by-product, "sake lees (sake-kasu)", as a commodity to eliminate waste.

・We sell sake by weight to reduce waste. -

Inami Shuzo Co., Ltd.

Akashi Sake Brewers Association

Click here for details

Click here for detailsWe want to create a system in which sustainable people can support and encourage the traditional industries of the region as farmers age. This initiative will weave new value into the future by creating opportunities for people to experience sake brewing that takes advantage of the local climate and local resources, and to learn how Yamada-nishiki, the king of sake rice produced in Miki City, is given new life as sake, and how new charms are sometimes created through maturation. We would like to make this an initiative to weave new values into the future. By creating such learning opportunities, we would like to support sustainable manufacturing by realizing SDG 15, "Protect the Abundance of Land," in addition to SDG 8, "Job Satisfaction and Economic Growth," and disseminate these efforts to the world.

-

TAKARA SHUZO CO., LTD.

Nadagogo Brewers Association

Click here for details

Click here for detailsThe word "宝(Takara)" in Takara Shuzo is derived from "from the rice field".

We are a company that receives many blessings from nature, such as abundant land, sunshine and rain, and the workings of microorganisms. We have held the "School in the Rice Paddies" every year since 2004 to express our gratitude for these blessings and to teach the next generation how to cherish the rich natural environment. Nature's bounty nurtures our precious food such as rice. The rice, birds, insects, plants and flowers, and we humans are all interconnected with each other.

At Takara Shuzo's "School in the Rice Paddies," participants plant seedlings, weed, and harvest the ears of rice with their own hands to experience the process of rice production, and observe plants, insects, and other living creatures in the rice paddies. Everyone's eyes sparkle at the plants, flowers, and creatures that they rarely have a chance to touch and see in the city. Our hope is that through the experience of the rice production process, participants will develop an appreciation for nature and a desire to cherish nature and food. -

KENBISHI SAKE Brewing Co. Ltd.

Nadagogo Brewers Association

Click here for details

Click here for detailsBy borrowing plots from aging farmers who are retiring and passing on rice cultivation, we are working to reduce the number of fallow rice fields and preserve the local environment. Inheriting the wooden bucket technique allows us to leave the technique to the next generation and to increase CO2 reduction by cutting down old trees and planting new ones. By being the only company in Japan with the technology to make thick straw rope, we are switching from nylon rope to straw rope and promoting the use of non-plastic materials. These wooden barrels and straw ropes are not only used for sake brewing, but are also used in local festivals, helping to pass on the culture.

Straw scraps are also used to make straw-roasted bonito tataki. We are able to recycle 100% of rice bran and sake lees by using them as raw materials and feed for other foods. We are working with the sake brewers' association to conserve groundwater and ensure that it is safe and reliable.

We have increased the number of mid-career hires and also have a 0% resignation rate over the past 10 years.

We are reducing energy consumption by installing solar panels and changing the coating on the roof to lower the temperature in the workplace during the summer. -

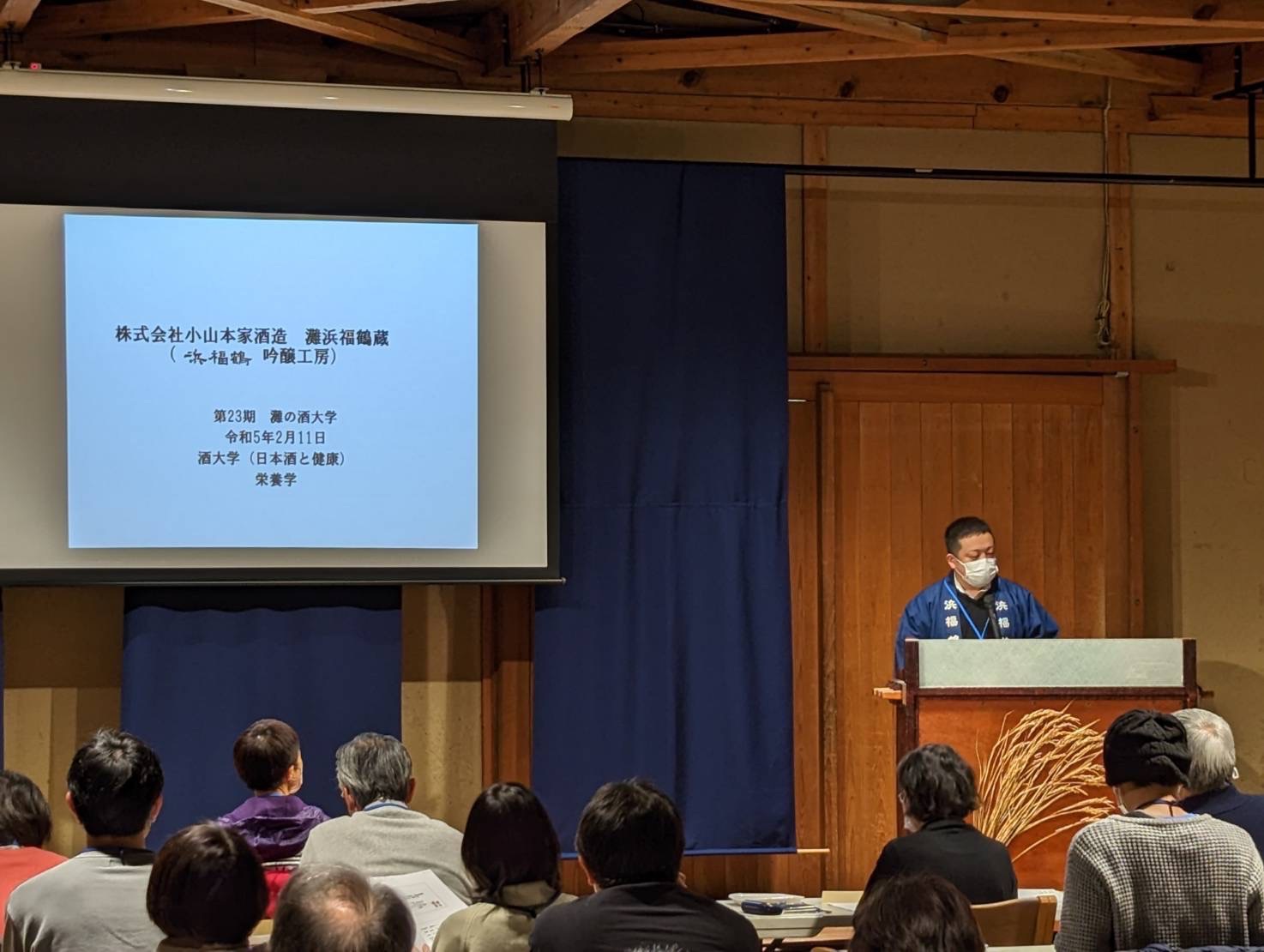

Koyama Honke Shuzo Co., Ltd.

Nada Ham...Nadagogo Brewers Association

Click here for details

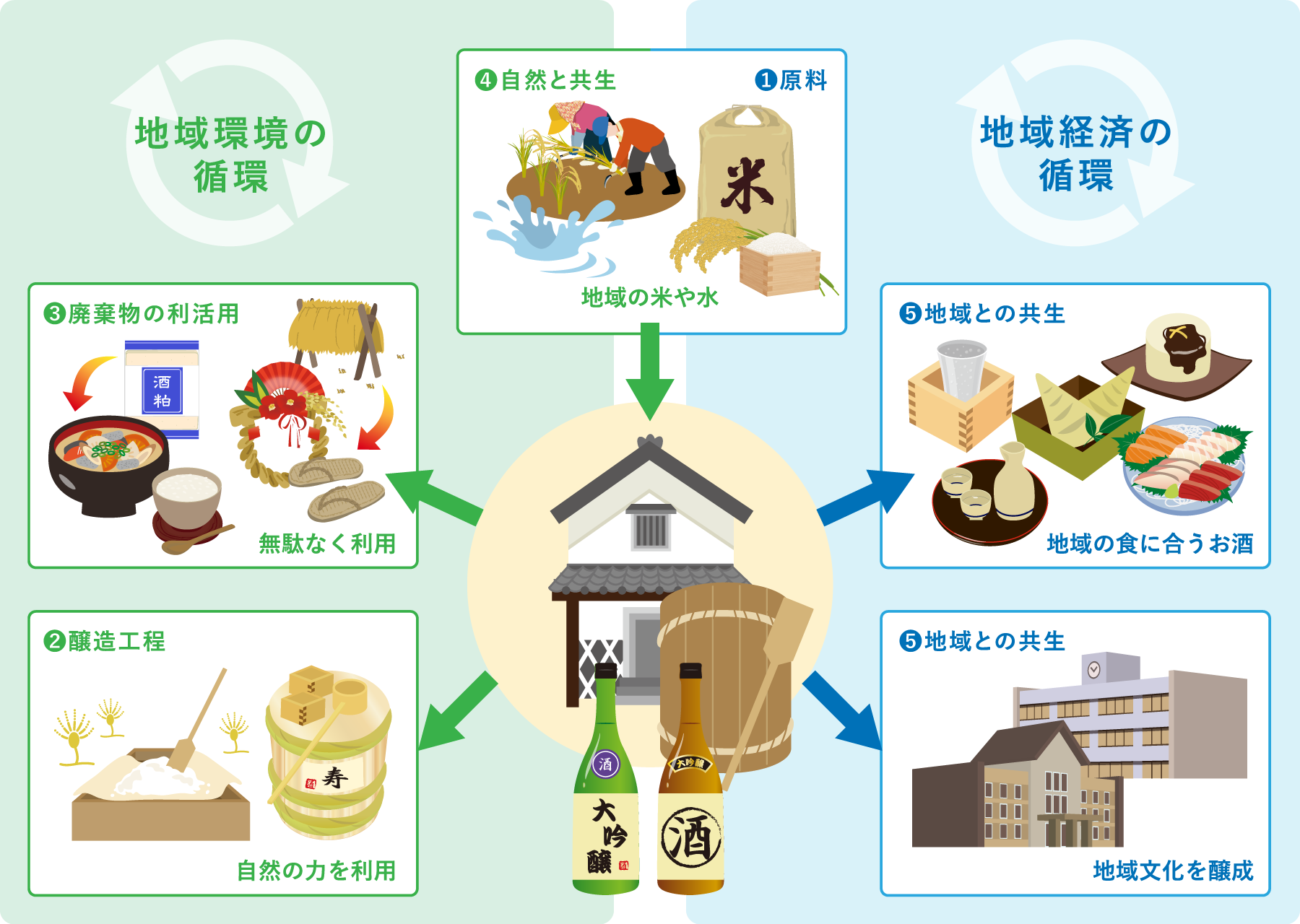

Click here for details"To be rooted in the community and contribute to society."

"To provide the world with a rich and affluent lifestyle through the pursuit of traditional sake making."

With these two themes, we, as a sake brewer, carry on the traditional sake brewing culture and educate the public about proper and healthy drinking. Specifically, the brewery allows visitors to observe the brewery's operations through glass windows, and guides explain the history of sake brewing and other aspects of the brewery. Seminars are held at local universities for people to learn about fermentation culture, and the ward office sponsors a sake university to educate people about healthy drinking. -

Sakuramasamune Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for detailsRegarding environmental issues, we are striving to reduce and control energy consumption by using reusable materials such as glass bottles and P-boxes, recycling efforts such as color-coding waste glass and collecting cardboard, using electric forklifts and switching to LED lights.

As part of our efforts to raise awareness of the importance of proper drinking as a brewery, we participate in FM Osaka's SDD (STOP DRUNK DRIVING) project and promote a campaign to eradicate drunk driving. We are grateful for the support of the local community in our hometown of Uozaki, where we are able to brew sake, and as a contribution to the local community, we hold a brewery cleanup on the first Saturday of November every year. In addition, we regularly clean up the area around the company, and in the event of a disaster, we plan to open the Hananokigura as an evacuation site in the event of a tsunami, thereby helping to create a better place to live. We also cooperate in educational activities, such as accepting students every year for junior high school try-it-yourself weeks and technical college internships.

Through Food Bank Kansai, we also provide support for activities to eliminate food waste and poverty, and we will continue to contribute to local communities and enrich people through sake brewing, which is part of our corporate philosophy. -

HAKUTSURU SAKE Brewing Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for detailsGoal 2: Zero hunger

・Hakutsuru Farm's activities also address the problems of aging farmers and abandoned farmland.

Goal 3: Health and welfare for all

・Promote awareness of proper drinking

Goal 4: High-quality education for all

・Lectures on business

・Rice planting and harvesting experience at Ginza Tenku Noen

Goal 5: Enforce gender equality

・Promote women's activities

Goal 6: Safe water

・Water quality preservation activities at Nadagogo Sake Brewers Association

Goal 7: Energy for All

・Introduce heat pumps and solar power generation

・Review local resources from an energy perspective

・Participation in "Local Design Council for Local Energy and Environment"

Goal 8: Both job satisfaction and economic growth

・Reform work styles, promote employment of people with disabilities

Goal 12: Sustainable production and consumption patterns

・Reduce CO2 emissions during production and transportation by making bottles lighter

・Use of biomass ink for part of film printing

・Design products with the 3Rs in mind

Goal 14: Preserve the richness of the sea

・Collaboration with JF Fishermen's Federation "Pride Fish Project"

Goal 15: Also protect the abundance of land

・Participation in the Rokko Mountain Range Green Belt Development Project

・Support for the activities of Peace & Nature, a non-profit organization that works to create sustainable food and the environment

Goals 9, 12, and 13

・Upcycle sake by-products

Purchased Hyogo Prefecture's 2022 fourth public bond issue (10-year green bond) in support of Hyogo Prefecture's SDGs initiatives. -

Ozeki Corporation

Nadagogo Brewers Association

Click here for details

Click here for detailsWe were one of the first companies to obtain ISO14001 certification for our environmental efforts in 1999, and we continue to maintain a production system that voluntarily complies with the standard. In 2015, we obtained FSSC22000 certification, an international standard for food safety, and have built a safe and secure manufacturing system as a food manufacturer. Our ESG initiatives based on these standards are deeply connected to the 17 goals of the SDGs, which aim to achieve a sustainable world, and we recognize that they are directly related to our company's social significance and creative business development for the future.

We believe that sake brewing is an ancient Japanese recycling-oriented industry. We will continue our business activities to create a food culture that is friendly to the environment, society, and people, and that is enjoyable to live in, based on the brewing and fermentation technologies we have accumulated over the years, and to realize a sustainable society.

1) The one-cup polycap is made of a carbon-neutral, low-environmental-impact bioplastic material, and we are actively developing products using eco-bottles made from recycled glass and recycled cullet. Forest certified paper is used as packaging material for packaged products. Some of our inks use plant-derived biomass inks, which are environmentally friendly.

2) In 2015, we installed a photovoltaic power generation plant on a former factory site in Sasayama City, Tanba, Japan, covering an area of about 2.4 hectares, and we are now engaged in power generation business. -

Fukunishiki co., ltd.

Yashiro Brewers Association

Click here for details

Click here for detailsOur company is participating in the "Local Natural Energy Sake for SDGs Project" because we share the values that the "Local Design Council for Natural Energy and Environment" (Secretariat: Kobe Shimbun) aims to achieve. 1Dairy farmers, 3 Yamada -nishiki producers, and 4 breweries have joined forces to launch this "Local Natural Energy Sake for SDGs Project" regards the enormous amount of food residues, substandard agricultural products, and other organic waste generated daily by people's "eating" activities as a mass of energy, and utilizes digested liquid (organic fertilizer), a byproduct of biogas extracted by fermenting "garbage" that has been disposed of by burning or other means.

The digested liquid is used as an organic fertilizer at Yuge Farm (Kita-ku, Kobe), which is involved in the biogas business, to grow Yamada-nishiki and brew a resource-recycling pure rice sake, "Local Natural Energy Sake: Meguru", using the most natural methods possible. -

Nihonsakari Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for detailsIn order to protect rice, water, and the natural environment, which are indispensable for sake brewing, we are actively working to reduce CO₂ emissions. Specifically, we are actively marketing products that use "bottle cans (made of aluminum)," which are lighter and more volumetrically efficient containers that can be expected to reduce the environmental impact of transportation and are also highly recyclable. Reduction of CO₂ emissions by increasing the ratio of LED lighting in the factory. We are also "paperless" by introducing electronic seals, encouraging data storage, and digitizing internal applications. In addition, we are actively adopting environmentally friendly materials for products and transportation. Paper containers, cardboard, straws, and other materials are being replaced with certified forest paper and biomass materials. The outer packaging of Kesera-Cera cosmetics is made of bagasse, which is derived from sugarcane and is used as an alternative raw material to wood pulp, thereby contributing to forest protection, CO₂ reduction, and energy conservation. In this way, we will actively promote "switching to materials with low environmental impact" and "efforts to reduce CO₂ emissions," and work to improve both our corporate activities that are friendly to the global environment and our customers' satisfaction.

-

TANAKA SHUZOJO

Himeji Brewers Association

Click here for details

Click here for detailsIn sake brewing, nothing is discarded in each step of the process. Rice is used and fermented, resulting in sake and sake lees (sake kasu). Sakekasu is consumed as is for food or used for pickles. Rice bran from rice polishing is in demand as rice oil, rice confectionery, and rice flour, depending on the category of rice.

We use the oldest type of equipment called "Ishikake-shiki Tenbin Shibori," which does not use any electricity or carbon energy and only five of them are in operation in Japan, to press the "moromi" made from fermentation. The weight of the natural stone is used to slowly press the rice over a period of three days using the principle of leverage. Although it is time-consuming and labor-intensive, the rich flavor is surprisingly different from that of products made in pursuit of efficiency.

In addition, since last year, we have been using organic farming methods for rice cultivation, and we brew our sake with Yamadanishiki produced in Hyogo Prefecture. The fertilizer used in organic farming is made from food scraps from school lunches and leftovers from restaurants and livestock manure, and no chemical fertilizers are used. By continuing this approach, we will reduce waste and promote recycling-oriented sake brewing.

(Right) Yamada-nishiki grown using organic farming methods.

(Front) Yamada-nishiki grown with organic fertilisers. The colour of the leaves is darker.

(Back) Yamada-nishiki grown with chemical fertilisers. -

Sawanotsuru Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for details・Effective use of sake lees (sake kasu).

・Effective use of rice bran.

・Reduction and proper disposal of waste.

・Clean-up activities along the Toga River and the sake brewery promenade.

・Sake brewery town development in Nishigo.

・Active use of forest certified paper (FSC) and biomass ink.

・Steam supply using waste heat from the power station.

・Participation in Miyamizu conservation activities

・Use of LED lights in company offices and factories.

・Cooperation with Yamada Nishiki farmers.

・Promotion of employee health.

・Promotion of work style reforms.

・Employee training and education system.

・Awareness-raising on proper drinking. -

KOBE SHU-SHIN-KAN BREWERIES,LTD.

Nadagogo Brewers Association

Click here for details

Click here for detailsKobe Shu-shin-kan has made it our Purpose (meaning of existence as a company) to "produce delicious sake with no environmental impact," and in October 2022, we launched "Fukuju Junmai-shu Eco Zero," the world's first sake with zero carbon dioxide (CO2) emissions (virtually zero) in the sake making process.

By converting to 100% renewable energy (Scope 2) and carbon neutral city gas (Scope 1), we have achieved net zero carbon dioxide emissions in the sake production process. We have also reduced energy consumption in the rice milling process by reducing rice polishing from 70% to 80%. The 80% polished rice is fermented slowly at low temperatures to bring out the rich earthy flavor of the rice while achieving a refreshing aftertaste. By using "Kyokai dried yeast" (No. 901), the sake mothering process was omitted and the fermentation period was shortened by 7 days. In addition, by applying a printed design to the bottle, a "label-less" design was created to convey an environmentally friendly (eco) message.

"Fukuju Junmai Sake Eco Zero" contributes to decarbonization in the food supply chain while pursuing a very natural taste. -

Kiku-Masamune Sake Brewing Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for details1) Contribute to a rich sake culture and healthy lifestyle

Carrying on the tradition of making sake yeast, making barrels at the Barrel Sake Meister Factory Developing functional alcoholic beverages that cut down on delicious sugar content, and developing healthy foods and food products using lactic acid bacteria and Sake Kasu.

2) Environmentally friendly activities to realize a sustainable future

Forest caretaker activities on Mt. Rokko, preservation activities of Yoshino cedar used as raw material for barrels, use of environmentally friendly materials (use of FSSC forest certified paper and rice ink as materials for recycled bottles and packaged products).

3) Active involvement in local communities

Support for Yamada-nishiki farmers through the village rice system, hiring and supporting the activities of people with disabilities as regular employees. -

KASUMITSURU CO.,LTD.

North Hyogo Sake Brewers Association

Click here for details

Click here for details・The company grows its own sake rice using organic fertilizer made from the crab shells of Matsuba crab and Kasumi crab, which are local specialties of Kasumi.

・A water sprinkler system using well water has been installed on the roof of the storage building. This has made it possible to reduce the amount of electricity used for air conditioning during the summer months.

・The lighting in the company is being converted to LED sequentially. We are reducing the amount of electricity used.

・Shrink film packaging has been eliminated for products packed in paper cartons. We have been able to reduce the use of petroleum, the raw material for shrink film, and the electricity used for packaging.

We will continue to promote higher quality and energy saving. -

Kizakura Co.,Ltd.

Tamba Sasayama Brewers Association

Click here for details

Click here for detailsBeginning in 2021, Kizakura has been recycling uniforms and work clothes that its employees have finished wearing through its dealers. Compared to conventional petroleum-based chemical fiber (polyester) production, manufacturers reduce CO2 emissions by about 55% by using recycled raw materials. Our company contributes to the SDGs by using work clothes made by manufacturers with a smaller environmental impact.

-

KING BREWING CO.,LTD.

Kakogawa Brewers Association

Click here for details

Click here for detailsThe Hinode Holdings Group has been promoting social contribution initiatives through its business activities to deliver safe, secure, reliable, and satisfying products to customers based on its corporate philosophy of "continuing to provide satisfaction and joy to people's lives."

1) We manufacture products made from local agricultural products, actively engage in exchanges with local residents, and support urban development initiatives. We have been certified as a "Regional Future Leading Company" selected by the Minister of Economy, Trade and Industry, which is expected to develop businesses that create high added value by taking advantage of regional characteristics and strongly drive economic ripple effects on local businesses and other entities in the region.

2) "Brewing lees" generated in the process of producing mirin (sweet sake) and sake are commercialized as "mirin kasuzuke no moto" (mirin pickling stock), and are also used as raw materials for Nara pickles and as animal feed. Furthermore, we have launched a new brand "ORYZAE JOY" using sake lees and are developing products that allow people to enjoy traditional Japanese fermented foods while taking care of their health and beauty.

-

Fukunishiki co., ltd.

Yashiro Brewers Association

Click here for details

Click here for detailsOur company is participating in the "Local Natural Energy Sake for SDGs Project" because we share the values that the "Local Design Council for Natural Energy and Environment" (Secretariat: Kobe Shimbun) aims to achieve. 1Dairy farmers, 3 Yamada -nishiki producers, and 4 breweries have joined forces to launch this "Local Natural Energy Sake for SDGs Project" regards the enormous amount of food residues, substandard agricultural products, and other organic waste generated daily by people's "eating" activities as a mass of energy, and utilizes digested liquid (organic fertilizer), a byproduct of biogas extracted by fermenting "garbage" that has been disposed of by burning or other means.

The digested liquid is used as an organic fertilizer at Yuge Farm (Kita-ku, Kobe), which is involved in the biogas business, to grow Yamada-nishiki and brew a resource-recycling pure rice sake, "Local Natural Energy Sake: Meguru", using the most natural methods possible.

-

Nihon no Koshukura Inc.

Kakogawa Brewers Association

Click here for details

Click here for detailsNihon no Koshukura Inc. checks the current status of sake breweries across Japan, buys sake that is out of business or has been stored for a long time and is not planned to be sold, stores it, recycles it as old sake and sells it.

In doing so, we support the traditional Japanese industry of sake brewing and contribute to the revitalisation of local economies and the creation of sustainable local economies.

In addition, by giving new value to sake that has been out of business or stored for a long time as old sake, we are working to reduce sake waste and make effective use of it.

In addition, koshu is produced by storing sake at room temperature in a brewery and maturing the sake, which is an environmentally friendly way of producing koshu through energy-neutral and CO2-free brewery operations.

We have established the company with 10 partner sake breweries across Japan to help pass on the culture of old sake, and we also work with 52 sake breweries in 22 prefectures across Japan.

We will continue to work for the future of koshu culture, to promote and enhance the value of koshu, and to make efforts for the development of Japanese sake. -

KING BREWING CO.,LTD.

Kakogawa Brewers Association

Click here for details

Click here for detailsThe Hinode Holdings Group has been promoting social contribution initiatives through its business activities to deliver safe, secure, reliable, and satisfying products to customers based on its corporate philosophy of "continuing to provide satisfaction and joy to people's lives."

1) We manufacture products made from local agricultural products, actively engage in exchanges with local residents, and support urban development initiatives. We have been certified as a "Regional Future Leading Company" selected by the Minister of Economy, Trade and Industry, which is expected to develop businesses that create high added value by taking advantage of regional characteristics and strongly drive economic ripple effects on local businesses and other entities in the region.

2) "Brewing lees" generated in the process of producing mirin (sweet sake) and sake are commercialized as "mirin kasuzuke no moto" (mirin pickling stock), and are also used as raw materials for Nara pickles and as animal feed. Furthermore, we have launched a new brand "ORYZAE JOY" using sake lees and are developing products that allow people to enjoy traditional Japanese fermented foods while taking care of their health and beauty.

-

SAKURA SAKE BREWING CO.,LTD.

Tamba Sasayama Brewers Association

Click here for details

Click here for details・We are promoting energy saving by switching to LED lighting in the factory.

・We plant chestnut trees and continue to manage the many cherry and plum trees that have been planted for some time.

・Since 2015, together with Group company Hakutsuru Farm, we have been cultivating Hakutsuru Nishiki and Gohyakumangoku, rice suitable for sake brewing, in our home town of Tanba Sasayama. We use rice produced in Tamba Sasayama City in all of its products, and is working to protect the environment, including land use.

・The rice wastewater generated during the brewing process is treated by micro-organisms in the factory and the residues are composted in the factory. The compost is shared with the Hakutsuru Farm and neighbouring communities, contributing to local agriculture. -

Karibaichi Sake Brewery Co., Ltd.

Tamba Sasayama Brewers Association

Click here for details

Click here for detailsKaribaichi Sake Brewery is working to achieve the SDGs goals through the initiatives listed below.

・We are working to preserve the local environment by growing sake rice in our own rice fields near the brewery.

・We are participating in a sake rice project in the Furuichi district of Tanba Sasayama, where our brewery is located, with the aim of creating a SATOYAMA Model that will last for 100 years. In this project, some of the sake rice is grown without pesticides, and other efforts are being made to cultivate the rice in a way that is considerate of the natural environment.

・We are promoting energy conservation by switching to LED lights throughout the brewery.

・We accept local junior high school students to participate in "Try It Again Week," an annual event held in Hyogo Prefecture, to encourage them to become interested in the local community and work through work experience.

・We are working to reuse bottles, collecting not only our own bottles but also those of other companies, washing them, and inspecting them. -

Kizakura Co.,Ltd.

Tamba Sasayama Brewers Association

Click here for details

Click here for detailsBeginning in 2021, Kizakura has been recycling uniforms and work clothes that its employees have finished wearing through its dealers. Compared to conventional petroleum-based chemical fiber (polyester) production, manufacturers reduce CO2 emissions by about 55% by using recycled raw materials. Our company contributes to the SDGs by using work clothes made by manufacturers with a smaller environmental impact.

-

YAEGAKI Sake&Spirits, Inc.

Himeji Brewers Association

Click here for details

Click here for detailsMaking sake requires a lot of water. In addition to brewing water, the water used for washing and other miscellaneous purposes is 30 to 50 times the amount of water used for the raw rice. Much of the water used is then discharged as wastewater. In particular, the wastewater from washing rice has a large environmental impact and must be discharged after appropriate wastewater treatment. Since 2016, our company has been using micro-organisms to methane ferment the wastewater and other substances generated in the sake production process. This methane fermentation reduces the eutrophic components in the wastewater and produces biogas that can be used more effectively. The biogas extracted from the methane fermentation is then returned to the company as fuel for the boilers used to produce steam and hot water for the steaming of rice and other processes at the factory.

(Photo left) Biogas holder (Photo right) Methane fermenter -

MEIJO SAKE BREWING CO., LTD.

Himeji Brewers Association

Click here for details

Click here for detailsSolar power generation, conversion of wastewater sludge into animal feed, conversion of sake lees into animal feed and fertilizer

-

TANAKA SHUZOJO

Himeji Brewers Association

Click here for details

Click here for detailsIn sake brewing, nothing is discarded in each step of the process. Rice is used and fermented, resulting in sake and sake lees (sake kasu). Sakekasu is consumed as is for food or used for pickles. Rice bran from rice polishing is in demand as rice oil, rice confectionery, and rice flour, depending on the category of rice.

We use the oldest type of equipment called "Ishikake-shiki Tenbin Shibori," which does not use any electricity or carbon energy and only five of them are in operation in Japan, to press the "moromi" made from fermentation. The weight of the natural stone is used to slowly press the rice over a period of three days using the principle of leverage. Although it is time-consuming and labor-intensive, the rich flavor is surprisingly different from that of products made in pursuit of efficiency.

In addition, since last year, we have been using organic farming methods for rice cultivation, and we brew our sake with Yamadanishiki produced in Hyogo Prefecture. The fertilizer used in organic farming is made from food scraps from school lunches and leftovers from restaurants and livestock manure, and no chemical fertilizers are used. By continuing this approach, we will reduce waste and promote recycling-oriented sake brewing.

(Right) Yamada-nishiki grown using organic farming methods.

(Front) Yamada-nishiki grown with organic fertilisers. The colour of the leaves is darker.

(Back) Yamada-nishiki grown with chemical fertilisers.

-

Inami Shuzo Co., Ltd.

Akashi Sake Brewers Association

Click here for details

Click here for detailsWe want to create a system in which sustainable people can support and encourage the traditional industries of the region as farmers age. This initiative will weave new value into the future by creating opportunities for people to experience sake brewing that takes advantage of the local climate and local resources, and to learn how Yamada-nishiki, the king of sake rice produced in Miki City, is given new life as sake, and how new charms are sometimes created through maturation. We would like to make this an initiative to weave new values into the future. By creating such learning opportunities, we would like to support sustainable manufacturing by realizing SDG 15, "Protect the Abundance of Land," in addition to SDG 8, "Job Satisfaction and Economic Growth," and disseminate these efforts to the world.

-

TAKARA SHUZO CO., LTD.

Nadagogo Brewers Association

Click here for details

Click here for detailsThe word "宝(Takara)" in Takara Shuzo is derived from "from the rice field".

We are a company that receives many blessings from nature, such as abundant land, sunshine and rain, and the workings of microorganisms. We have held the "School in the Rice Paddies" every year since 2004 to express our gratitude for these blessings and to teach the next generation how to cherish the rich natural environment. Nature's bounty nurtures our precious food such as rice. The rice, birds, insects, plants and flowers, and we humans are all interconnected with each other.

At Takara Shuzo's "School in the Rice Paddies," participants plant seedlings, weed, and harvest the ears of rice with their own hands to experience the process of rice production, and observe plants, insects, and other living creatures in the rice paddies. Everyone's eyes sparkle at the plants, flowers, and creatures that they rarely have a chance to touch and see in the city. Our hope is that through the experience of the rice production process, participants will develop an appreciation for nature and a desire to cherish nature and food. -

KENBISHI SAKE Brewing Co. Ltd.

Nadagogo Brewers Association

Click here for details

Click here for detailsBy borrowing plots from aging farmers who are retiring and passing on rice cultivation, we are working to reduce the number of fallow rice fields and preserve the local environment. Inheriting the wooden bucket technique allows us to leave the technique to the next generation and to increase CO2 reduction by cutting down old trees and planting new ones. By being the only company in Japan with the technology to make thick straw rope, we are switching from nylon rope to straw rope and promoting the use of non-plastic materials. These wooden barrels and straw ropes are not only used for sake brewing, but are also used in local festivals, helping to pass on the culture.

Straw scraps are also used to make straw-roasted bonito tataki. We are able to recycle 100% of rice bran and sake lees by using them as raw materials and feed for other foods. We are working with the sake brewers' association to conserve groundwater and ensure that it is safe and reliable.

We have increased the number of mid-career hires and also have a 0% resignation rate over the past 10 years.

We are reducing energy consumption by installing solar panels and changing the coating on the roof to lower the temperature in the workplace during the summer. -

Koyama Honke Shuzo Co., Ltd.

Nada Ham...Nadagogo Brewers Association

Click here for details

Click here for details"To be rooted in the community and contribute to society."

"To provide the world with a rich and affluent lifestyle through the pursuit of traditional sake making."

With these two themes, we, as a sake brewer, carry on the traditional sake brewing culture and educate the public about proper and healthy drinking. Specifically, the brewery allows visitors to observe the brewery's operations through glass windows, and guides explain the history of sake brewing and other aspects of the brewery. Seminars are held at local universities for people to learn about fermentation culture, and the ward office sponsors a sake university to educate people about healthy drinking. -

Sakuramasamune Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for detailsRegarding environmental issues, we are striving to reduce and control energy consumption by using reusable materials such as glass bottles and P-boxes, recycling efforts such as color-coding waste glass and collecting cardboard, using electric forklifts and switching to LED lights.

As part of our efforts to raise awareness of the importance of proper drinking as a brewery, we participate in FM Osaka's SDD (STOP DRUNK DRIVING) project and promote a campaign to eradicate drunk driving. We are grateful for the support of the local community in our hometown of Uozaki, where we are able to brew sake, and as a contribution to the local community, we hold a brewery cleanup on the first Saturday of November every year. In addition, we regularly clean up the area around the company, and in the event of a disaster, we plan to open the Hananokigura as an evacuation site in the event of a tsunami, thereby helping to create a better place to live. We also cooperate in educational activities, such as accepting students every year for junior high school try-it-yourself weeks and technical college internships.

Through Food Bank Kansai, we also provide support for activities to eliminate food waste and poverty, and we will continue to contribute to local communities and enrich people through sake brewing, which is part of our corporate philosophy. -

HAKUTSURU SAKE Brewing Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for detailsGoal 2: Zero hunger

・Hakutsuru Farm's activities also address the problems of aging farmers and abandoned farmland.

Goal 3: Health and welfare for all

・Promote awareness of proper drinking

Goal 4: High-quality education for all

・Lectures on business

・Rice planting and harvesting experience at Ginza Tenku Noen

Goal 5: Enforce gender equality

・Promote women's activities

Goal 6: Safe water

・Water quality preservation activities at Nadagogo Sake Brewers Association

Goal 7: Energy for All

・Introduce heat pumps and solar power generation

・Review local resources from an energy perspective

・Participation in "Local Design Council for Local Energy and Environment"

Goal 8: Both job satisfaction and economic growth

・Reform work styles, promote employment of people with disabilities

Goal 12: Sustainable production and consumption patterns

・Reduce CO2 emissions during production and transportation by making bottles lighter

・Use of biomass ink for part of film printing

・Design products with the 3Rs in mind

Goal 14: Preserve the richness of the sea

・Collaboration with JF Fishermen's Federation "Pride Fish Project"

Goal 15: Also protect the abundance of land

・Participation in the Rokko Mountain Range Green Belt Development Project

・Support for the activities of Peace & Nature, a non-profit organization that works to create sustainable food and the environment

Goals 9, 12, and 13

・Upcycle sake by-products

Purchased Hyogo Prefecture's 2022 fourth public bond issue (10-year green bond) in support of Hyogo Prefecture's SDGs initiatives. -

Ozeki Corporation

Nadagogo Brewers Association

Click here for details

Click here for detailsWe were one of the first companies to obtain ISO14001 certification for our environmental efforts in 1999, and we continue to maintain a production system that voluntarily complies with the standard. In 2015, we obtained FSSC22000 certification, an international standard for food safety, and have built a safe and secure manufacturing system as a food manufacturer. Our ESG initiatives based on these standards are deeply connected to the 17 goals of the SDGs, which aim to achieve a sustainable world, and we recognize that they are directly related to our company's social significance and creative business development for the future.

We believe that sake brewing is an ancient Japanese recycling-oriented industry. We will continue our business activities to create a food culture that is friendly to the environment, society, and people, and that is enjoyable to live in, based on the brewing and fermentation technologies we have accumulated over the years, and to realize a sustainable society.

1) The one-cup polycap is made of a carbon-neutral, low-environmental-impact bioplastic material, and we are actively developing products using eco-bottles made from recycled glass and recycled cullet. Forest certified paper is used as packaging material for packaged products. Some of our inks use plant-derived biomass inks, which are environmentally friendly.

2) In 2015, we installed a photovoltaic power generation plant on a former factory site in Sasayama City, Tanba, Japan, covering an area of about 2.4 hectares, and we are now engaged in power generation business. -

Nihonsakari Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for detailsIn order to protect rice, water, and the natural environment, which are indispensable for sake brewing, we are actively working to reduce CO₂ emissions. Specifically, we are actively marketing products that use "bottle cans (made of aluminum)," which are lighter and more volumetrically efficient containers that can be expected to reduce the environmental impact of transportation and are also highly recyclable. Reduction of CO₂ emissions by increasing the ratio of LED lighting in the factory. We are also "paperless" by introducing electronic seals, encouraging data storage, and digitizing internal applications. In addition, we are actively adopting environmentally friendly materials for products and transportation. Paper containers, cardboard, straws, and other materials are being replaced with certified forest paper and biomass materials. The outer packaging of Kesera-Cera cosmetics is made of bagasse, which is derived from sugarcane and is used as an alternative raw material to wood pulp, thereby contributing to forest protection, CO₂ reduction, and energy conservation. In this way, we will actively promote "switching to materials with low environmental impact" and "efforts to reduce CO₂ emissions," and work to improve both our corporate activities that are friendly to the global environment and our customers' satisfaction.

-

Sawanotsuru Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for details・Effective use of sake lees (sake kasu).

・Effective use of rice bran.

・Reduction and proper disposal of waste.

・Clean-up activities along the Toga River and the sake brewery promenade.

・Sake brewery town development in Nishigo.

・Active use of forest certified paper (FSC) and biomass ink.

・Steam supply using waste heat from the power station.

・Participation in Miyamizu conservation activities

・Use of LED lights in company offices and factories.

・Cooperation with Yamada Nishiki farmers.

・Promotion of employee health.

・Promotion of work style reforms.

・Employee training and education system.

・Awareness-raising on proper drinking. -

KOBE SHU-SHIN-KAN BREWERIES,LTD.

Nadagogo Brewers Association

Click here for details

Click here for detailsKobe Shu-shin-kan has made it our Purpose (meaning of existence as a company) to "produce delicious sake with no environmental impact," and in October 2022, we launched "Fukuju Junmai-shu Eco Zero," the world's first sake with zero carbon dioxide (CO2) emissions (virtually zero) in the sake making process.

By converting to 100% renewable energy (Scope 2) and carbon neutral city gas (Scope 1), we have achieved net zero carbon dioxide emissions in the sake production process. We have also reduced energy consumption in the rice milling process by reducing rice polishing from 70% to 80%. The 80% polished rice is fermented slowly at low temperatures to bring out the rich earthy flavor of the rice while achieving a refreshing aftertaste. By using "Kyokai dried yeast" (No. 901), the sake mothering process was omitted and the fermentation period was shortened by 7 days. In addition, by applying a printed design to the bottle, a "label-less" design was created to convey an environmentally friendly (eco) message.

"Fukuju Junmai Sake Eco Zero" contributes to decarbonization in the food supply chain while pursuing a very natural taste. -

Kiku-Masamune Sake Brewing Co., Ltd.

Nadagogo Brewers Association

Click here for details

Click here for details1) Contribute to a rich sake culture and healthy lifestyle

Carrying on the tradition of making sake yeast, making barrels at the Barrel Sake Meister Factory Developing functional alcoholic beverages that cut down on delicious sugar content, and developing healthy foods and food products using lactic acid bacteria and Sake Kasu.

2) Environmentally friendly activities to realize a sustainable future

Forest caretaker activities on Mt. Rokko, preservation activities of Yoshino cedar used as raw material for barrels, use of environmentally friendly materials (use of FSSC forest certified paper and rice ink as materials for recycled bottles and packaged products).

3) Active involvement in local communities

Support for Yamada-nishiki farmers through the village rice system, hiring and supporting the activities of people with disabilities as regular employees.

-

KONISHI BREWING CO., LTD.

Itami Brewers Association

Click here for details

Click here for detailsKonishi Brewery recognises that its 470-odd year history is a series of sustainable activities. Recent activities include the promotion of environmental protection initiatives such as the use of lightweight bottles and environmentally friendly materials, as well as the acquisition of FSSC 22000 certification, an international standard, to ensure that we can always provide 'food safety and security'.

In the first place, the sake brewing industry is aware that the activities required on the planet today are to pass on fermentation techniques and food culture and to protect the 'traditional sake brewing culture'.

In order to contribute more than ever before to the sound development of the region, we will also be involved in the sound upbringing of young people and school education through Shubukan, one of the three largest private dojos in Japan, and work to build the foundations for a better society.

In the brewing industry, which used to be a male-dominated society, we have also placed great importance on the success of women. Currently, the percentage of women in management positions is 26%, far exceeding the Japanese standard of more than 10%. We aim to reach 30% as soon as possible.

Based on the corporate philosophy of "Elegance and Innovation", this phrase is that "the essence of sake will always remain the same in the constant pursuit of newness and challenge.", we will continue to be with the local community in Itami, the birthplace of sake, and develop from our history and traditions to become a world-class company in the future. -

Itami Oimatsu Brewing Co., Ltd.

Itami Brewers Association

Click here for details

Click here for detailsFor sustainable sake brewing, we are committed to environmental considerations and value our relationship with the local Itami community.

・The brewery and sales office have switched to LEDs and energy-saving production lines.

・The company collects and reuses bottles.

・The brewery uses vegetable oil ink containing plant-derived ingredients and paper bags made from recycled paper containing recycled paper pulp.

・Selling sake lees produced in the brewing process and developing curry, bread, rice crackers and other products using sake lees.

・The company has also developed curry, bread, rice crackers and other products using sake lees.

・Work experience for junior high school students during 'Try It Again Week' in the prefecture. -

OKAMURA SHUZOJO

Itami Brewers Association

Click here for details

Click here for details・The raw materials used are sake rice grown in the company's own fields and local sake rice. The brewery sells sake brewed in harmony with nature, using local water and working in cooperation with local people to protect nature.

・The brewery also sells sake lees from the brewing process, and in collaboration with a local pastry chef, it sells pound cakes made from sake lees and soaps containing junmai sake.

・The female head of the brewery is the master brewer, and she is responsible for everything from rice cultivation to sake brewing.

・The brewery is also committed to the environment, using electric forklifts and LED lights to reduce power consumption in the factory, using reusable bottles and returnable P-boxes, taking broken bottles to recycling companies, and separating the polyethylene and aluminium crowns of sake bottles.

-

Konotomo Sake Brewery Co.,Ltd.

North Hyogo Sake Brewers Association

Click here for details

Click here for detailsUsually, the large amount of 'sake-kasu' that is always produced in the sake brewing process becomes industrial waste if it remains unsold. In our brewery, sake lees are used as board lees and pickle lees, while the unprocessed sake lees from ginjo sake are used in shochu production. The method is to add the ginjo lees during the shochu making process to dissolve and saccharify them, as well as to ferment them to increase the shochu making rate.

The lees from shochu are also very rich in amino acids, and in 2010 the lees were transferred to the Osaka Prefectural Engei Senior High School, where they are used as part of the food for bee keeping. This initiative was initiated to help break down the situation in the beekeeping industry in Japan, where the horticultural industry is unable to supply the bee swarms it needs, starting with the mass disappearance of honey bees, which is a problem worldwide. As a countermeasure to the shortage of bees, it is particularly important to develop healthy bees, and the beekeeping industry usually uses 'substitute pollen' during periods when flowers are scarce. However, there is no good 'substitute pollen' in Japan, so beekeepers rely on expensive imports. The Osaka Prefectural Engei Senior High School has therefore produced a purely domestic 'substitute pollen'. Shochu lees, which would otherwise have been discarded, are used to nurture bees and play a part in creating a habitable environment. -

TAJIME General Partnership

North Hyogo Sake Brewers Association

Click here for details

Click here for details・The lighting in the company will be converted to LED sequentially. We will continue to reduce electricity consumption.

・We will use locally grown rice for all of our sake brewing.

・Since 2005, we have been brewing sake using specially cultivated rice based on the "Stork Breeding Agricultural Method".

This is the first year that we are using the "Stork Breeding Agricultural Method" for sake rice, and we were one of the first to address environmental issues, and we are still working on it. The "Stork Breeding Agricultural Method" is an agricultural method that aims to create a rich culture, region, and environment where storks can live by nurturing delicious rice and a variety of living creatures. For example, to create a habitable environment for living creatures, various techniques are employed, such as "winter waterlogging" to flood rice fields in winter, the use of organic fertilizers from the seedling stage, and safe and secure cultivation using no or reduced pesticides (limited to those with low fish toxicity). We grow living creatures that serve as food for storks, protect storks, and create a rich Tajima.

・We use recycled bottles to protect the environment.

・We sell all sake by-product, "sake lees (sake-kasu)", as a commodity to eliminate waste.

・We sell sake by weight to reduce waste. -

KASUMITSURU CO.,LTD.

North Hyogo Sake Brewers Association

Click here for details

Click here for details・The company grows its own sake rice using organic fertilizer made from the crab shells of Matsuba crab and Kasumi crab, which are local specialties of Kasumi.

・A water sprinkler system using well water has been installed on the roof of the storage building. This has made it possible to reduce the amount of electricity used for air conditioning during the summer months.

・The lighting in the company is being converted to LED sequentially. We are reducing the amount of electricity used.

・Shrink film packaging has been eliminated for products packed in paper cartons. We have been able to reduce the use of petroleum, the raw material for shrink film, and the electricity used for packaging.

We will continue to promote higher quality and energy saving.